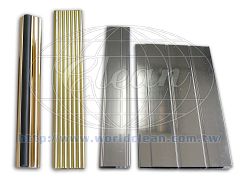

SE-NSP-35L Chemical Polishing

Chemical polishing for Aluminum is a simple dipping process to obtain brightness surface and it’s much better than ordinary electropolishing. Although Aluminum mirror polishing techniques is publicly in method and formula, that is Aluminum profile being mechanical polished first and then chemical polished to make surface has various styles of shines, it’s not able to widely sell in the market. The reasons are chemical consumption too high, difficult quality control, exhaust generation, costly waste water treatment … etc, so the production cost is high so price of end product is unacceptable in the market. Besides, it’s a common technique to have mechanical polishing before anodizing, however, brightness of surface is not comparable to stainless steel. That also makes sales hard.

Composition of conventional polishing chemical

Concentrated phosphoric acid, sulfuric acid, nitric acid, additives are strong oxidizer. When concentration changes, brightness of Aluminum surface also changes and is hard to control. In the polishing process, the phosphoric acid was continuously consumed. The most convenient way to control concentration of phosphoric acid is to record the original water level of it and maintaining by adding more phosphoric acid. According to experience, every time adding phosphoric acid should be the same proportion of nitric acid, and keeping nitrate acid concentrations maintain at 3.5-6.5% V/V to get gross surface. Nitrate acid is the necessary chemical.

Problems of conventional polishing chemical

Following are general chemical polishing problems for Aluminum polishing anodizer:

- Chemical polishing factory generally must do polishing in suburban area or at night.

- Generating huge amount of yellow fume, causing environmental problems.

- Due to high concentrations of chemicals, Aluminum parts are only allowed to stay in air about 30 seconds until being water rinsed after polishing. Because polishing chemical will corrode the Aluminum and make brightness recession, serious water marks, pinholes, scrapped materials and low yield.

- Because Aluminum can not remain in the air too long, amount of polishing chemical drag-out is high, causing huge amount of chemical being brought to water rinsing tanks.

- A large quantity of wastewater will raise cost of wastewater treatment.

- Yellow fume is the big problem for waste air treatment. Cost of waste air treatment will increase as well.

- Surface brightness will decrease after anodizing. The thicker the oxidation film is, the more brightness decreasing will be.

Environmental friendly WORLDCLEAN Chemical Polishing agent solves all the problems above and receives many positive comments from our customers.

|

WORLDCLEAN SE-NSP-35L

|

Conventional

tri-acid Polishing |

Electro-polishing

|

|

|

Waste Air

|

White Fume

|

Yellow Fume

|

White Fume

|

|

Waste Water

|

Low

|

High

|

High

|

|

Chemical Consumption

|

Low

|

High

|

High

|

|

Chemical Adding

|

Simple

|

Experienced

|

Experienced

|

|

Chemical Management

|

Easy

|

Hard

|

Hard

|

|

Surface brightness After Polishing

|

OK

|

OK

|

OK

|

|

Surface brightness After Desmutting

|

OK

|

Decreasing

|

Decreasing

|

|

Surface brightness After Anodizing

|

OK

|

Decreasing More

|

Decreasing More

|

|

Power Consumption

|

Low

|

High

|

High

|

|

Yield Rate

|

High

|

Very Low

|

Low

|